Road Pavement Preservation Planning and Design Should Focus on Performance

Category: Blog Articles By: David Helm

Accomplishing roadway rehab projects is a major effort that requires a laser-like focus on funding options and design deadlines. It’s as though the construction is almost academic compared to all the heavy lifting you have to do to get your project completed.

Road pavement design focuses on drainage and the thickness and strength of the materials. Simply build it “to spec” and all is well (hopefully).

Another important factor in achieving long-term pavement performance is the durability of the asphalt itself. Durability is the ability of your road to withstand the natural effects of weather, including moisture penetration and freeze/thaw cycling.

Asphalt Basics

It is the adverse effects of weather that break down the pavement surface and create a rough ride. Pavement deterioration begins the day your roadway is laid.

We often look at a hot mix pavement as a single entity. In reality, pavements are a combination of stone and liquid asphalt cement. It’s the asphalt cement that glues the rock together. The “glue” provides resilience and waterproofing. So even though the asphalt cement only makes up about six percent of the pavement – it is the most important part of the mix.

According to asphalt technologists, “The performance of asphalt cement as a binder in Hot Mix Asphalt is determined by its physical properties, which in turn are determined directly by its chemical composition.1”

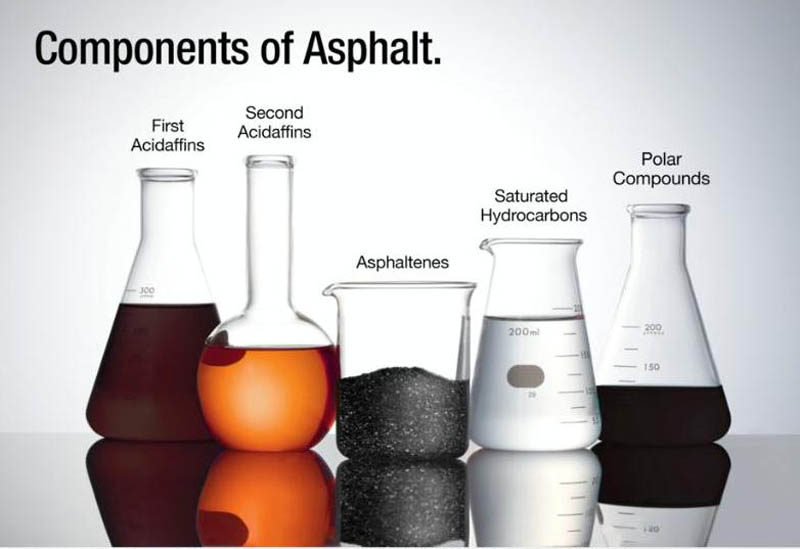

Asphalt cement consists of two main petroleum groups: asphaltene and maltenes, which themselves are made up of a variety of components, e.g. first acidaffins, second acidaffins, saturated hydrocarbons and polar compounds.

- Asphaltenes are solid when separated and provide body and hardness, sort of like pencil lead.

- Maltenes make up most of the liquid asphalt and are what make it sticky and flexible.

Even before the liquid asphalt arrives at your job site, the heat of manufacturing has begun to degrade its consistency. Once your road is installed, the natural asphalt components known as maltenes are further degraded from oxidation and weathering.

Here’s what aging looks like over a 10-year period:

One inexpensive road pavement preservation option for getting long-term performance is to seal the new paving project with Maltene Replacement Technology (MRT). Moisture is asphalt’s worst enemy. Building the preservation treatment into the cost of your original road project is inexpensive and will improve asphalt durability. Create a better asphalt, get a better pavement.

The MRT process naturally returns to asphalt the same compounds that have been depleted during the heat of manufacturing and subsequent oxidation. After it is applied, a maltene-based rejuvenator deeply penetrates the roadway, restoring the asphalt’s maltene components, thereby providing the long-term performance needed for a sustainable pavement solution.

Here’s what MRT looks like in action:

Will existing pavements benefit from this technology?

Existing pavements can also benefit from Maltene Replacement Technology. The best time to apply a maltene-based rejuvenator is inside a four-year window – i.e., before the pavement begins to show significant cracking or surface raveling.

MRT accomplishes two important tasks:

- First, it combines with the asphalt cement to create an in-depth seal that shields your asphalt roads from weather.

- Second, MRT restores the consistency of your asphalt.

What’s the bottom line?

- Maintains smooth pavement

- Avoids costly end-of-life repairs

- Extends pavement life by four to five years

- Costs under one dollar per square yard applied

- Creates a better asphalt

With today’s emphasis on thoughtfully evaluating pavement solutions for their sustainability attributes, MRT delivers the ultimate in sustainable performance – the significant extension of a roadway’s service life.